Fermentation is a common technology for producing bioethanol, and it can be obtained from a variety of biomass materials. Lifeasible provides technical consulting services for the fermentation production of bioethanol, and is committed to providing customers with high quality project design service that can solve various professional problems in the production process. Lifeasible also provide process optimization service to enable customers to produce higher quality bioethanol.

The fermentation process mainly includes three processes which are pretreatment, fermentation, and product refining. The pretreatment stage prior to biological fermentation needs to be specifically treated according to the characteristics of the raw materials. Pretreatment is essential for the production of bioethanol, affecting the subsequent process and product quality. The main purpose of this process is to obtain a sugar solution that can be used for fermentation. Pretreatment methods for this process include physical technology, chemical technology, and biological technology. Lifeasible offers pretreatment process optimization services by selecting the best pretreatment method and parameters based on the characteristics of different biomass feedstock, helping to increase ethanol production and reduce production cost. For example, cellulosic biomass can be pretreated by grinding and hydrolysis. Sugary biomass raw materials such as sugar cane first need to be ground, and then sugar is extracted to prepare a sugar-containing solution such as sugar cane juice for fermentation process. Pretreatment methods of starch-containing biomass raw materials such as corn are classified into wet grinding and dry grinding. The wet grinding method requires soaking, grinding and separating to obtain starch from raw materials, and finally liquefying and saccharifying the starch before fermentation. The dry milling process includes grinding, beating, amylase catalysis, liquefaction and saccharification.

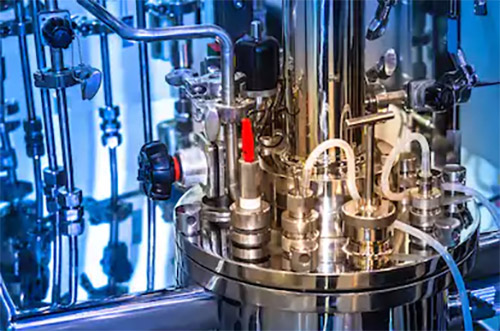

The fermentation process mainly converts sugar into ethanol through the action of microorganisms. The technical support services provided by Lifeasible for bioethanol production can help customer optimize the selection of yeast strains in fermentation process and the control of fermentation temperature. Besides, we design the fermentation process according to the production conditions and production requirements of customers to help customers solve professional problems in the fermentation process.

The comprehensive processes involved in hydrolysis and fermentation in bioethanol production include simultaneous saccharification and fermentation (SSF), simultaneous saccharification and co-fermentation (SSCF), consolidated bioprocessing (CBP), etc. Lifeasible is experienced in these fermentation processes and can provide you with a variety of services, such as fermentation process selection, fermentation process optimization and fermentation process technology consulting.

The product obtained after fermentation needs to be further separated and purified to obtain bioethanol. The usual separation and purification methods include adsorption dehydration and distillation. Years of bioenergy experience for Lifeasible can help you design optimal bioethanol purification processes by combining influence factors such as production conditions, production cost and product quality.

Lifeasible has always been committed to providing the highest quality bioethanol production technology consulting, project design, and process optimization services. If you have difficulties in bioethanol process selection and fermentation strain selection, or you want to improve the bioethanol production technology, increase productivity, and reduce production cost, Lifeasible can be a good choice for you, please feel free to contact us for more information.

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

July 13, 2024