Bioenergy is a renewable energy resource, which is environmentally friendly. The process of bioenergy production often involves enzymatic reactions. Physicochemical pretreatment technologies are effective methods for increasing the accessibility of enzymes and then improving the conversion rate of biomass materials. Lifeasible provides technical consulting, project design and program optimization services related to physicochemical pretreatment. We ensure high quality services that can help customers solve various technical difficulties in the physicochemical pretreatment process.

Physicochemical pretreatment is a type of technology suitable for biomass pretreatment, including steam-explosion, liquid hot water, wet oxidation, supercritical fluid, and ammonia fiber explosion.

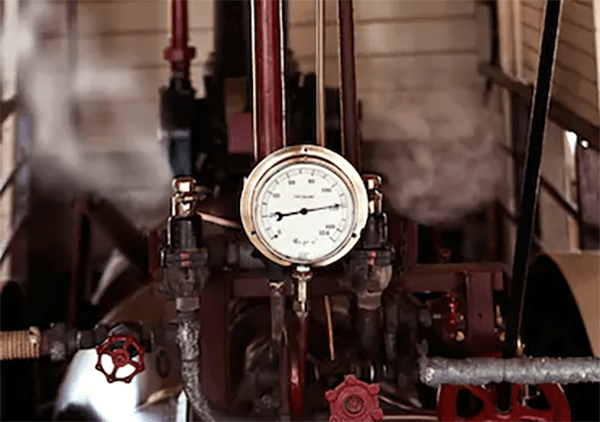

Steam-explosion

Steam-explosion is a physicochemical pretreatment method commonly used in lignocellulosic materials. This pretreatment method uses both chemical and physical techniques to process biomass. It destroys the structure of lignocellulosic materials and increases the accessibility of enzyme. Steam-explosion pretreatment enables biomass material to withstand high temperatures and pressures in a short period of time, and then quickly decompresses. Acid catalysts can be added to reduce residence time and temperature. Steam-explosion pretreatment is environmentally friendly and relatively low cost.

Liquid hot water

The reaction conditions of liquid hot water are similar to steam-explosion. This pretreatment method uses high temperature and pressure to keep the water liquid to promote the dissolution and separation of hemicellulose, as well as make the fiber more easily exposed. Liquid hot water can promote the improvement of enzyme digestibility and the increase of bioenergy yield. In addition, liquid hot water generally does not require the addition of chemical catalysts, so it has less impact on the environment. This pretreatment method produces fewer inhibitory compounds, which can further ensure the higher conversion rate of biomass materials.

Wet oxidation

Wet oxidation refers to the use of water and air or oxygen to pretreat biomass materials at high temperatures. It is beneficial for the separation of cellulose from lignin and hemicellulose in biomass materials, and the accessibility of enzymes. The main reaction in this pretreatment technology is the formation of acid and oxidation reaction during hydrolysis, and the reaction temperature is an important parameter of this technology. Wet oxidation can be combined with alkali pretreatment to further improve the conversion rate of raw materials.

Supercritical fluid

Supercritical fluid is a kind of liquid that can be used in a state above the critical temperature and critical pressure. Supercritical fluid not only has the same density as liquids, but also has the diffusibility and transmission characteristics of gas. Supercritical fluid can penetrate the crystal structure of lignocellulosic materials, and simplify the separation process by the difference of partition coefficients and solubility of components. These properties effectively enhance the cellulose digestibility, and have great potential in pretreatment.

Ammonia fiber explosion (AFEX)

AFEX is also similar to steam-explosion pretreatment, for AFEX, biomass materials first cause lignocellulose to expand under high pressure and moderate temperature, and then quickly depressurize to destroy the fiber structure. Unlike steam-explosion, AFEX uses liquid anhydrous ammonia and reacts at lower temperature. AFEX pretreatment can effectively reduce the crystallinity of cellulose and improve the accessibility of enzymes, thereby increasing the conversion rate of biomass materials. AFEX is suitable for materials with low lignin content, such as herbs and agricultural wastes. There is almost no inhibitor formation during AFEX pretreatment, and the ammonia can be recycled.

There are many process parameters that affect the effects of physicochemical pretreatment technologies. Optimization of these parameters can effectively improve bioenergy production and cost-effectiveness. Lifeasible provides technical consulting, project design and program optimization services for these physicochemical pretreatment technologies. Our experts have extensive expertise in physicochemical pretreatment processes and can help you solve multiple technical problems. In addition, our experts can design individual solutions according to your production needs and production conditions, or optimize existing process parameters. If you are seeking technical support services in physicochemical pretreatment of biomass materials, Lifeasible is your reliable choice. Please feel free to contact us.

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

July 13, 2024