Silk fibroin (SF) extracted from silkworms has become a popular biomaterial due to its excellent biocompatibility, mechanical properties, tunable degradation, easy processing, and abundant supply. As a material with excellent processing properties, SF can be processed into various forms with different structures.

Silk fibroin biomaterials have the following characteristics:

(1) Excellent in vivo biocompatibility;

(2) Excellent physical properties, especially mechanical properties;

(3) Degradability of safe by-products;

Lifeasible can customize silk fibroin biomaterial products with different structures for you. The structure design types include monomer structure and multi-layer structure, which can meet your various project needs. In addition, we can also provide you with customized product solutions to help you complete the project requirements as soon as possible.

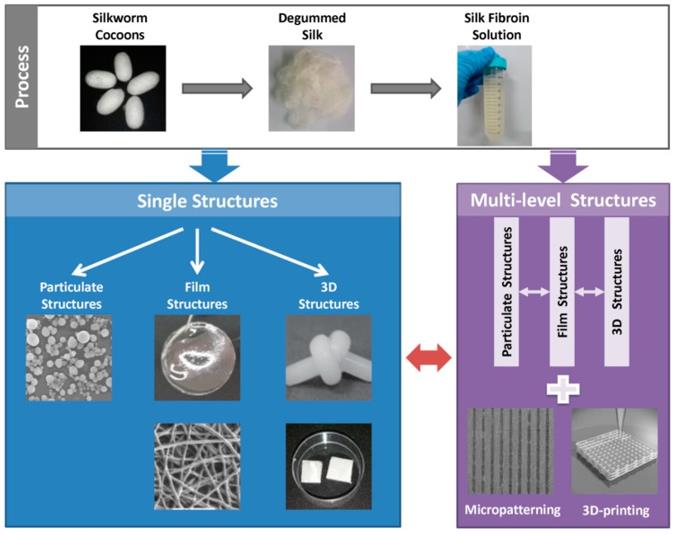

Through different treatments, SF can be arranged into various forms, such as solutions, powders, fibers, films, hydrogels, and sponges; this allows SF to build structures at many different scales, ranging from nano, micro, and macro dimensions.

Fig.1 Structural design of SF-based biomaterials from single structures to multi-level structures. (Qi et al., 2017)

Fig.1 Structural design of SF-based biomaterials from single structures to multi-level structures. (Qi et al., 2017)

As a professional silk product service provider, in addition to providing customers with silk fibroin performance modification services, we can also provide structural design of silk fibroin biomaterials and customize different types of products for you.

Due to the excellent processability of SF, various forms of SF-based biomaterials can be fabricated using different processing methods. Degumming is the first step in silk processing. The degummed silk fibers are then dissolved in a high molarity chaotropic salt solution such as lithium bromide or ionic liquid. Salts are subsequently removed by dialysis. SF can also be extracted directly from the posterior silk gland.

1. Single structure design

1) Various methods can be used to prepare silk fibroin materials with granular structures. 2) Silk fibroin film can be prepared by casting silk fibroin aqueous solution, spin coating, vertical deposition, and spin-assisted layer-by-layer assembly. 3) The gelation of SF can be induced by sonication, vortexing, heating, solvent treatment, photocrosslinking, and electrogelation.

2. Multi-layer structure design

Three-dimensional printing (3DP) is applied in the field of biomaterials, concentrated SF solution as ink, the ink is deposited through fine nozzles to form a precisely controlled complex array of silk fibers in a layer-by-layer sequence, and different SF 3D structures are obtained. Thanks to the development of 3D printing technology, SF can be precisely built in pre-designed specific structures to meet various requirements.

In addition to customizing the structure of silk fibroin biomaterial products for you, we can also provide you with product analysis and testing, including shape testing, etc., to provide you with product integration services.

The project team has a professional silk and spider silk development background and rich work experience and has efficient real-time consulting capabilities and execution capabilities.

Professionals provide solutions to customers, respond quickly, help customers solve problems the first time, and provide product and technology update information in time.

If you are interested in our services, or if you want a service not listed above, please feel free to contact us, and our staff will customize a professional product solution for you.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

July 13, 2024