In addition to mimicking natural spider silk proteins to form protein fibers, recombinant spider silk proteins can also be processed and assembled into thin films, hydrogels, nanoparticles, and other forms according to their different structural features to impart more biological functions. The recombinant spider silk proteins have distinct repetitive sequences, and each type of spider silk protein has different and distinctive motifs, so the combination of the motifs of each type of spider silk protein can be finely tuned and slightly modified to highlight its excellent biological properties. Lifeasible can modify recombinant spider silk proteins to produce novel functional polymers, including chemical and genetic engineering modifications.

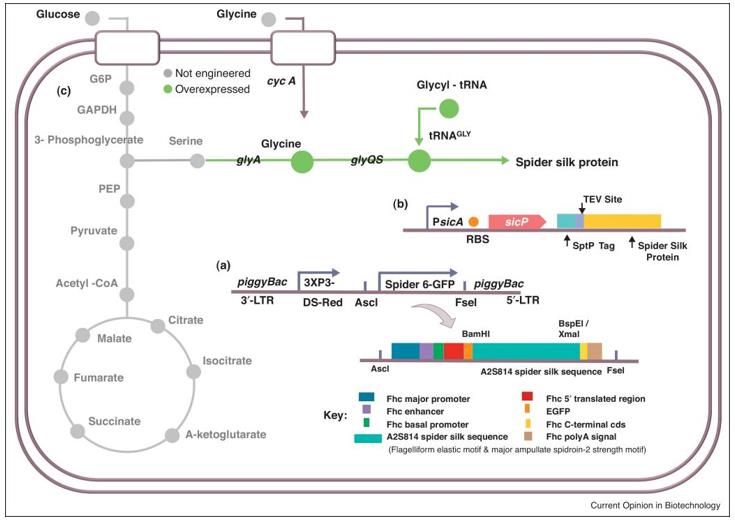

Fig.1 Representative strategies used to produce recombinant spider silk proteins. (Chung et al., 2012)

Fig.1 Representative strategies used to produce recombinant spider silk proteins. (Chung et al., 2012)

1. Chemical modifications

The core domain of spider silk proteins is stretched in an aqueous solution, making chemical modification of spider silk proteins simplified, and coupling in solution facilitates the incorporation of small functional molecules into larger materials. The sites for modification of recombinant spider silk proteins are the glutamate and aspartate residues at the carboxyl terminus of the protein and the serine and tyrosine residues at the hydroxyl terminus. Lifeasible can provide professional product customization solutions to help you perform modification services at the target sites.

2. Genetic engineering modifications

The functional properties of recombinant spider silk proteins can be expanded at the molecular level by fusing the sequence of the functional peptide or protein with that of the silk. This hybrid silk not only allows the acquisition of new, complete functions but also avoids the subsequent chemical modification step. Several modification methods were used to obtain recombinant spider silk proteins of comparable strength to natural spider silk fibers. Our team used transgenic silkworms to express a silkworm/spider chimeric silk protein that can stably embed the recombinant spider silk into its spatted silk. Such composite silk fibers are, on average, more tenacious than parental domestic silk fibers and even comparable to natural spider silk fibers; the molecular weight of recombinant spider silk proteins can also be increased by using in vitro splicing reactions of protein introns, where spider silk proteins fused with protein introns splice into each other in vitro to produce a tandem of Flag proteins.

The above modifications can help you solve problems in developing applications for recombinant spider silk proteins and tailor solutions for your projects.

We can provide services for preparing modified recombinant spider silk proteins into spider silk fibers and provide morphological observation and performance testing of spider silk fibers.

1. Morphological observation

The morphology of spider fibers is observed by scanning electron microscopy.

2. Determination of mechanical properties

The mechanical properties of the spider fibers were tested using a nano-tensiometer. The spider fibers were stretched at a certain speed until they broke. The force profile of the spider fibers was obtained by software, and the related mechanical properties were calculated.

If you are interested in our services, or if you want a service not listed above, please feel free to contact us, and our staff will customize a professional product solution for you.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

July 13, 2024